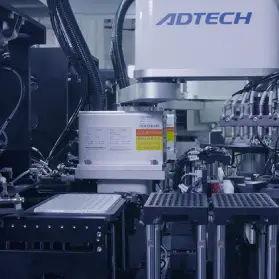

Focus on customer needs,

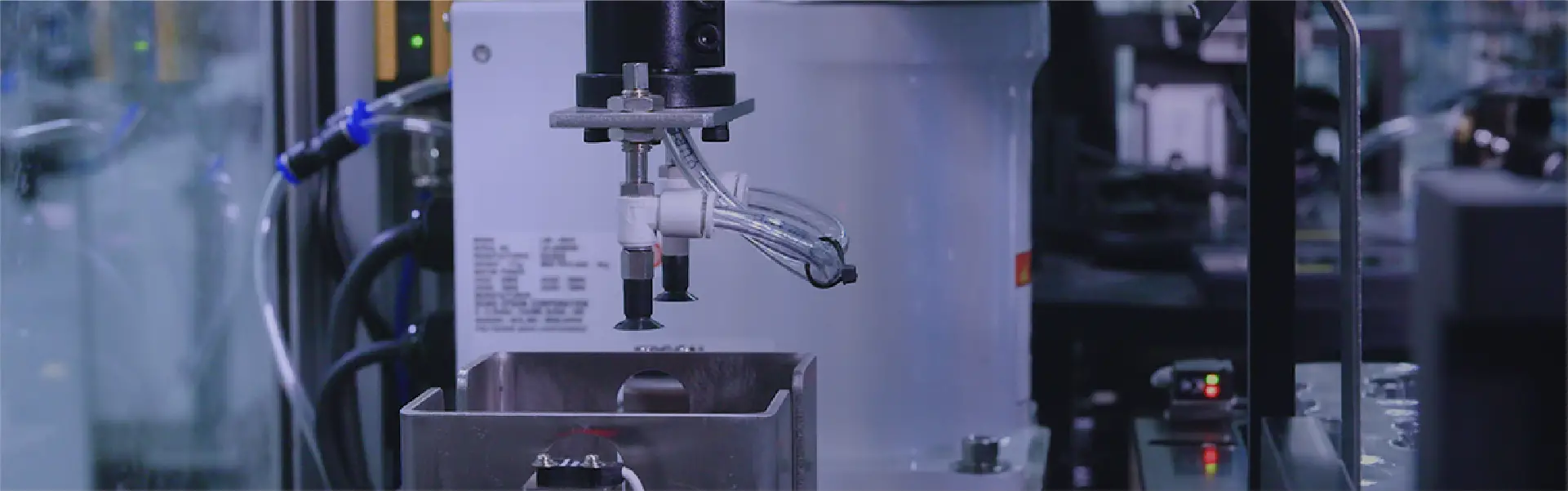

provide the ultimate technology and service

Continue to create value for customers, employees and shareholders

provide the ultimate technology and service

Continue to create value for customers, employees and shareholders

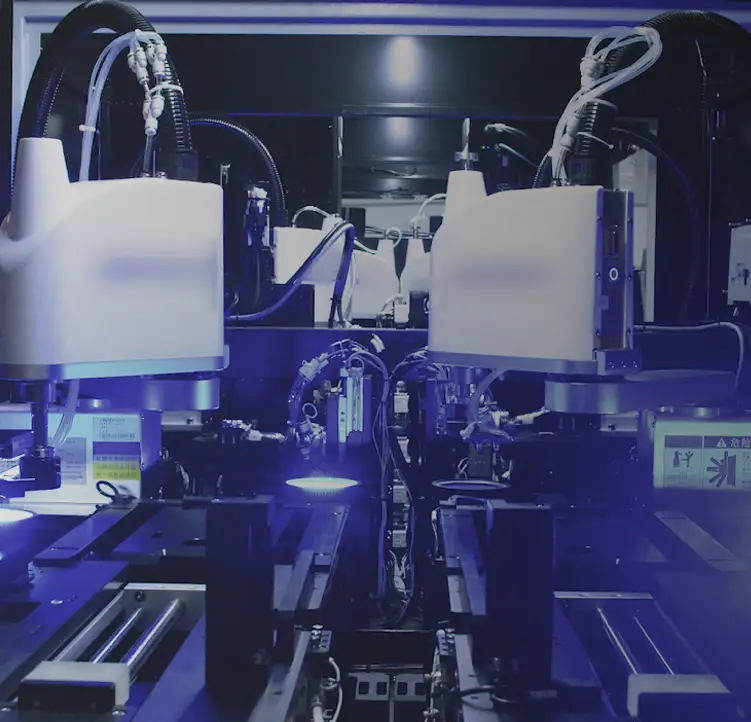

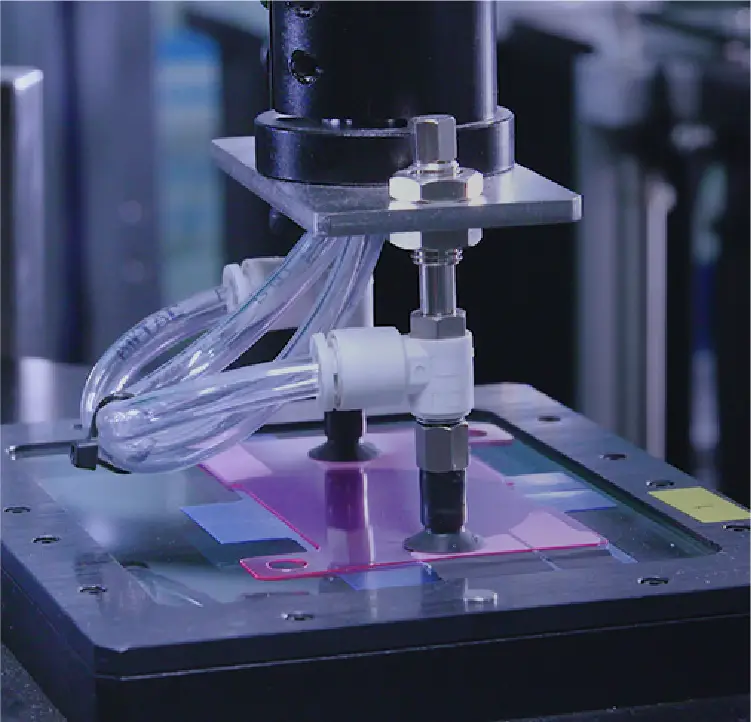

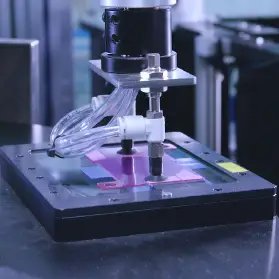

Focus on intelligent manufacturing

Committed to creating value for global precision manufacturing enterprises

Committed to creating value for global precision manufacturing enterprises

The world's leading provider of intelligent vision detection solutions

苏公网安备 32059002003195号

苏公网安备 32059002003195号